Advanced Analysis of Computational Fluid Dynamics

SIMULIA CFD Simulation

SIMULIA CFD Simulation

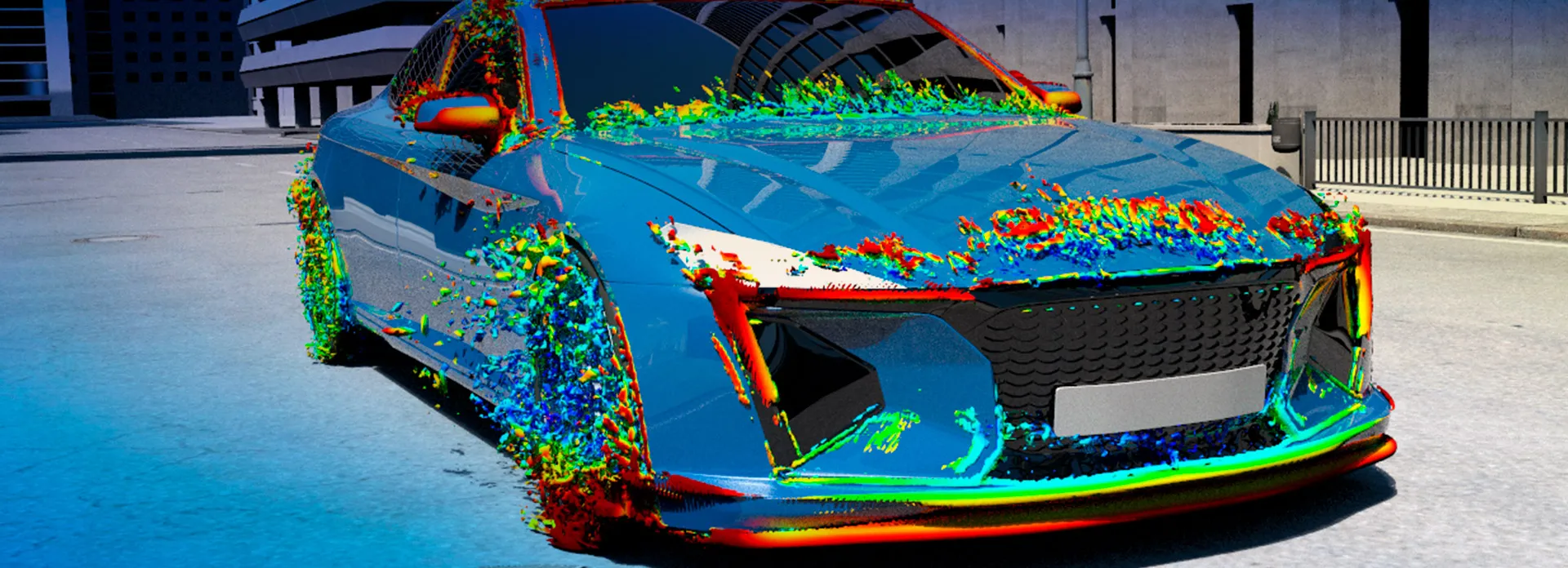

SIMULIA’s CFD solutions deliver fast, high-fidelity simulations for accurate real-world performance prediction. Powered by PowerFLOW, XFlow, and Fluid Dynamics Engineer, these technologies enable engineers to analyze both internal and external flows, optimize designs, and accelerate innovation. Embedded within the 3DEXPERIENCE platform, SIMULIA CFD provides scalable, automated, and multiphysics-driven simulation capabilities for industries ranging from aerospace and automotive to energy and manufacturing.

PowerFLOW is a CFD software using transient Lattice Boltzmann physics to simulate real-world fluid, thermal, and acoustic behavior. It enables early design evaluation, eliminating manual meshing, supporting complex geometries, and ensuring scalable, high-fidelity results across industries.

Explore More

XFlow is a high-fidelity, mesh-free CFD software using Lattice Boltzmann technology to simulate complex fluid dynamics, multiphase flows, and moving parts. With automatic lattice generation and GPU acceleration, it delivers fast, detailed insights for advanced lubrication and transient simulations.

Explore MoreEnhance design accuracy, quality, and performance with advanced simulation capabilities.

Utilize Abaqus and fe-safe technologies to gain precise structural insights under various loading conditions.

Integrate structural simulations early in the design process to prevent issues and optimize product performance.

Reduce costs and time-to-market by replacing physical prototypes with virtual testing and simulation.

Ensure consistent product lifespan and performance through advanced durability assessments.

Meet noise, vibration, and safety regulations to enhance the user experience and ensure product safety.

Explore how simulation empowers innovation across multiple engineering domains.

Use virtual prototypes to test and refine product designs under real-world stressors before physical production.

Assess stiffness, strength, and failure modes to maintain product reliability and safety.

Cut costs by identifying design flaws early, eliminating the need for expensive physical testing.

Simulate and mitigate noise and vibration, ensuring comfort and user satisfaction.

Test product longevity and reliability over time without the need for real-world testing scenarios.