Smart Scheduling for Agile, High-Performance Manufacturing

Delmia Ortems

Delmia Ortems

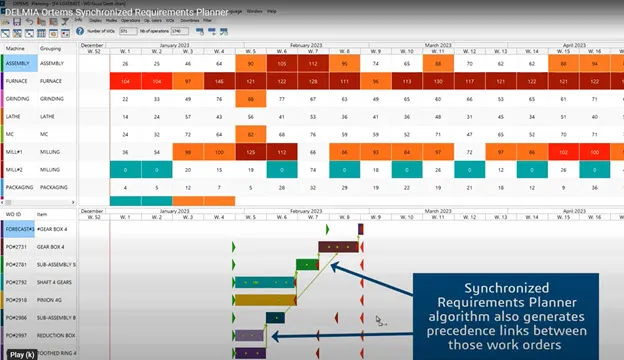

DELMIA Ortems delivers advanced planning, scheduling and optimisation capabilities to manufacturers intent on improving resource utilisation, shortening lead times and aligning production with demand. It extends traditional MES by offering detailed scheduling that incorporates constraints, real-time changes and optimisation across the supply-chain.

Advanced scheduling, resource optimisation, and real-time manufacturing adaptability for high-performance operations.

Considers machines, labour, materials and constraints for accurate planning.

Maximise throughput and minimise idle time across manufacturing assets.

Respond instantly to disruptions for agile and reliable operations.

Integrates production schedules with upstream and downstream flows.

Simulate “what-if” scenarios and optimise planning outcomes.

Improve agility, stabilise operations, and enhance throughput with intelligent scheduling and optimisation tools.

Ideal for manufacturers needing precise and flexible resource scheduling.

Adapts schedules to machine failures, shortages, or bottlenecks in real time.

Aligns production with demand and material flows to stabilise inventory.

Improves on-time delivery and accelerates manufacturing throughput.

Reveals inefficiencies and strengthens plant-wide utilisation.