Augmented Reality That Transforms How Manufacturing Gets Done

DELMIA Augmented Experience

DELMIA Augmented Experience

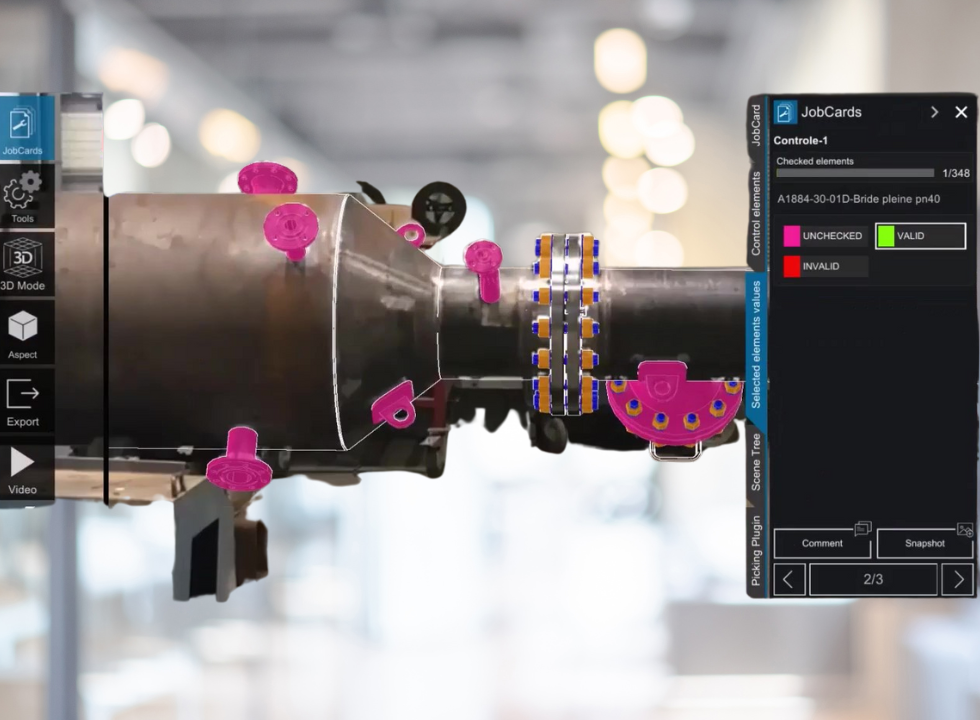

DELMIA Augmented Experience brings advanced augmented-reality (AR) and computer-vision capabilities into manufacturing operations, enabling interactive work instructions, step-by-step guidance and intelligent quality inspections in real time. It enhances human performance, reduces errors and accelerates training and execution on the factory floor.

Augmented-reality workflows, computer-vision inspection, and connected digital execution for modern manufacturing.

Provides augmented-reality guidance for complex assembly, maintenance and inspection tasks.

Uses computer-vision and digital-twin reference models for accurate defect detection.

Links AR workflows with the manufacturing operations ecosystem for physical-digital convergence.

Supports mobile devices, wearables and head-mounted displays for shop-floor usage.

Enables quick onboarding, skill transfer and consistent task execution across global sites.

Enhance assembly, inspection, training, and maintenance through immersive AR and digital-twin–connected workflows.

Ideal for aerospace, defence, automotive and similar lines where guided assembly and inspection are critical.

Helps technicians with real-time AR overlays and step-by-step instructions on equipment.

Improves consistency, reduces human error and strengthens traceability in inspection processes.

Supports on-the-job learning for varying skill levels and globally distributed teams.

Connects digital twin data with real-world operations to improve visibility, feedback and continuous improvement.